Secret Behind Dyson Bladeless Fans: Unveiling the Cool Technology

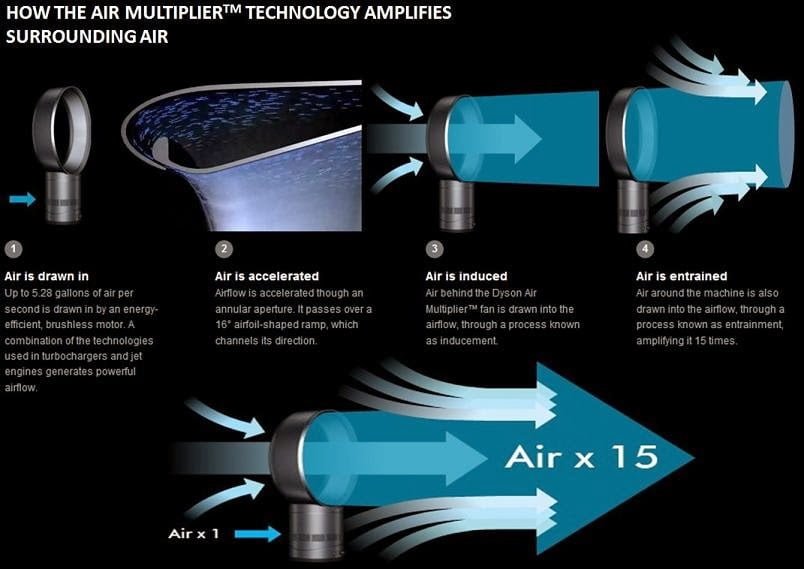

The inner workings of the Dyson bladeless fan have intrigued consumers since its debut. Unlike traditional fans with visible and often dust-collecting blades, the Dyson fan boasts a clean design with a mysteriously strong airflow. They call it the Air Multiplier™ technology. It uses physical principles of inducement and entrainment of surrounding air, effectively amplifying the initial airflow.

Understanding the technology behind this fan involves looking at the base, where a motor works to draw in air. This air is then pushed through narrow openings around the ring above it, creating a steady stream of air.

The absence of blades makes the fan safer for homes with children and pets, and easier to clean. Dyson claims its innovative approach to airflow results in a 15 times increase of the air drawn into the unit.

The appeal lies not just in its function but also in the improvements made over the years. Dyson engineers focused on reducing noise without compromising power, leading to a feature known as the Hemholtz cavity designed to capture the sound from the motor.

As a result, newer models are up to 75 percent quieter than their predecessors. The combination of form and function embodies the potential of modern technology to reinvent even the simplest of home appliances.

The Concept of Bladeless Fans

Bladeless fans, such as the Dyson bladeless fan, represent a significant leap in the evolution of air-moving devices, merging innovative engineering with a sleek, bladeless design.

Evolution from Traditional Fans

Traditional fans rely on the rapid rotation of blades to cut through the air, creating a breeze. The Dyson bladeless fan, however, signifies a redesign of the conventional fan, where the visible blades are entirely absent. This has helped create safer, easier to clean, and aesthetically more pleasing devices for air circulation.

Principle of Operation

The operation of a bladeless fan, specifically the Dyson Air Multiplier, begins with an impeller housed within the base. Air is drawn in and accelerated, passing over an aerofoil-shaped ramp.

This is where the principle of inducement and entrainment comes into play. Additional air is pulled in from the surroundings by the accelerating airflow, amplifying the initial breeze.

The engineering behind this method is how a gentle puff of wind transforms into a seamless, powerful airflow emanating from the fan.

Advantages of Dyson Bladeless Fans

Dyson bladeless fans, known for their innovative technology, offer a range of benefits that go beyond the capabilities of traditional fans. They combine safety with a modern design, making them a distinctive choice for both homes and offices.

Safety and Ease of Maintenance

The absence of spinning blades makes Dyson bladeless fans much safer for homes with children and pets. They are designed without grilles or visible heating elements, removing the risk of fingers or paws getting caught.

Maintenance is significantly simplified, as the lack of blades and grilles makes them easy to clean; a simple wipe down with a cloth is often enough to keep them in pristine condition.

Aesthetics and Design

Dyson fans are not only functional but also boast a sleek and attractive appearance.

Their modern and minimalist design is an aesthetic plus, effortlessly blending into contemporary decor and saving space. Many users consider their Dyson fan a statement piece that enhances the appearance of their room.

Air Quality Improvement

Some Dyson bladeless fans, such as the Dyson Pure Cool, serve a dual purpose as both a fan and an air purifier.

They are designed to improve air quality by removing allergens, pollutants, and fine particles. Thus, they not only cool the air but also make it cleaner and fresher to breathe, which is especially beneficial for those with allergies or respiratory concerns.

Their efficiency in air purification makes them a valuable addition to any space concerned with air quality.

Dyson’s Patented Air Multiplier Technology

Dyson’s Air Multiplier technology has revolutionized the design and function of fans by providing a consistent stream of smooth air without the use of visible blades. This innovative approach not only enhances performance but also addresses the noise problem commonly associated with traditional fans.

Engineering Behind Air Multiplier

Dyson’s bladeless fans, also known as Air Multipliers, operate by drawing air into the base of the machine using a brushless electric motor that operates quietly and efficiently.

The technology amplifies the surrounding air, resulting in a powerful, uninterrupted airflow that provides consistency and performance. The absence of spinning blades means airflow is smooth, without the choppy feeling you get from conventional fans.

Noise Reduction Techniques

The process of noise reduction was a significant focus during the development of the Air Multiplier.

Dyson engineers employed several techniques to make their fans quieter.

By analyzing the noise and manipulating airflow pathways within the fan, they reduced turbulence and, consequently, sound.

The result was a fan that is up to 75 percent quieter than its predecessors, tackling the noise problem associated with more conventional fans without compromising the fan’s overall performance.

The Science of Airflow

Dyson bladeless fans, also known as Air Multipliers, showcase a remarkable leap in the creation of a smooth air stream and energy efficiency in fan design. They utilize innovative technologies to enhance airflow and performance without the blades found in traditional fans.

Creating a Smooth Air Stream

Dyson’s bladeless fans leverage a phenomenon called inducement and entrainment to produce a smooth stream of air.

Air is drawn from the surroundings and accelerated through an annular aperture. This action amplifies the surrounding air, resulting in a smooth and powerful airflow that is free of the buffeting caused by spinning blades.

The bladeless design not only reduces noise but also eliminates the choppy air delivery, making the fan’s output steadier and more pleasant.

Energy Efficiency and Performance

The design of Dyson’s Air Multiplier focuses on energy efficiency and high-performance delivery of air.

By optimizing the way air is drawn in and propelled, the fans are engineered to consume less energy while maximizing airflow.

They achieve this through a combination of careful aerodynamic design and energy-efficient motors, ensuring that the fans are both environmentally friendly and cost-effective to run.

Performance is further improved by incorporating features like Dimmer-Switch control, allowing users to precisely adjust airflow to their liking.

User Experience and Features

Dyson Bladeless Fans stand out with their user-centric design that combines ease of use with a host of features aimed at delivering a customized cooling experience.

Control and Customization

Operation: Users can easily operate the Dyson Bladeless Fans with a simple and intuitive remote control.

The remote allows for quick access to all the fan’s functions, including the adjustment of fan speeds and activation of the oscillation feature. The fan’s ability to oscillate ensures that airflow is distributed evenly across the room.

Timers: In addition, the fans come with built-in timers which can be set to turn the fan off at predetermined intervals, providing convenience and energy efficiency.

Comparisons with Other Brands

When compared with traditional fan brands like Lasko, Dyson Bladeless Fans offer a leap in technology similar to the transition from traditional vacuum cleaners to Dyson’s cyclonic models. Below is a comparison of features:

- Noise: Dyson fans are engineered to be quieter, reducing audio disturbances.

- Safety: With no exposed blades, Dyson fans are safer, eliminating the risk of injury.

- Maintenance: The lack of blades makes cleaning the fan a hassle-free task, unlike traditional fans.

Research and Development at Dyson

Dyson’s journey from initial concept to final product exemplifies a rigorous research and development process. Staffed with a team of dedicated engineers, the company invests heavily in creating prototypes, embracing innovative engineering techniques, and refining its products.

From Prototypes to Market

Dyson’s commitment to R&D begins with prototyping.

Each Dyson bladeless fan is the culmination of numerous prototypes — with Dyson’s quieter fan model alone undergoing 640 iterations.

This relentless pursuit ensures that only the most efficient and user-friendly version reaches the market.

James Dyson, the founder, has established a culture where products are developed through countless iterations to solve problems innovatively and creatively.

Continuous Innovation

At Dyson, engineering is a continuous cycle of improvement, not just a one-time effort. The company’s bladeless fans saw a significant redesign when engineers worked meticulously on making them 75 percent quieter.

This task was accomplished without compromising the airflow efficiency—a testament to the ingenuity of the Dyson engineering team. The research team, comprising engineers and other specialists, constantly explores new avenues to make every version of a product better than the last.

Environmental Impact and Sustainability

Dyson’s approach to fan design reflects a commitment to environmental sustainability. They focus on the production of energy-efficient appliances that contribute to energy savings.

Dyson’s Commitment to Energy Savings

Dyson’s bladeless fans are engineered with energy conservation in mind. They often include features such as sensors. These sensors detect and capture microscopic pollutants. This ensures the fan only operates when necessary, subsequently reducing power consumption.

For instance, the Air Multiplier technology is designed to provide a powerful airflow without the need for fast-spinning blades. Fast-spinning blades can result in enhanced energy efficiency.

They also focus on developing products that provide considerable energy savings compared to traditional designs. By capturing 99.95% of airborne particles, Dyson purifiers maintain clean air with minimal energy use.

This technological innovation aligns with Dyson’s broader sustainability goals. Their commitment extends beyond individual products to encompass a company-wide ethos aimed at reducing the environmental footprint.